The standard size of a brake bleeder screw is 5.16 inches x 3.8 inches. Brake bleeder screws are an essential component in the braking system of vehicles, allowing for the release of air or fluid to ensure optimal performance.

In this article, we will explore the dimensions and specifications of brake bleeder screws, shedding light on their importance and how they contribute to maintaining safe and efficient braking systems for various types of vehicles.

So, What Size Is a Brake Bleeder Screw Exactly? Let’s find out!

Table of contents

What Is a Brake Bleeder Screw?

A brake bleeder screw is a small, threaded screw located on the brake caliper or wheel cylinder of a vehicle.

It is designed to release trapped air or old brake fluid from the braking system during the process of bleeding the brakes.

What Size Is a Brake Bleeder Screw?

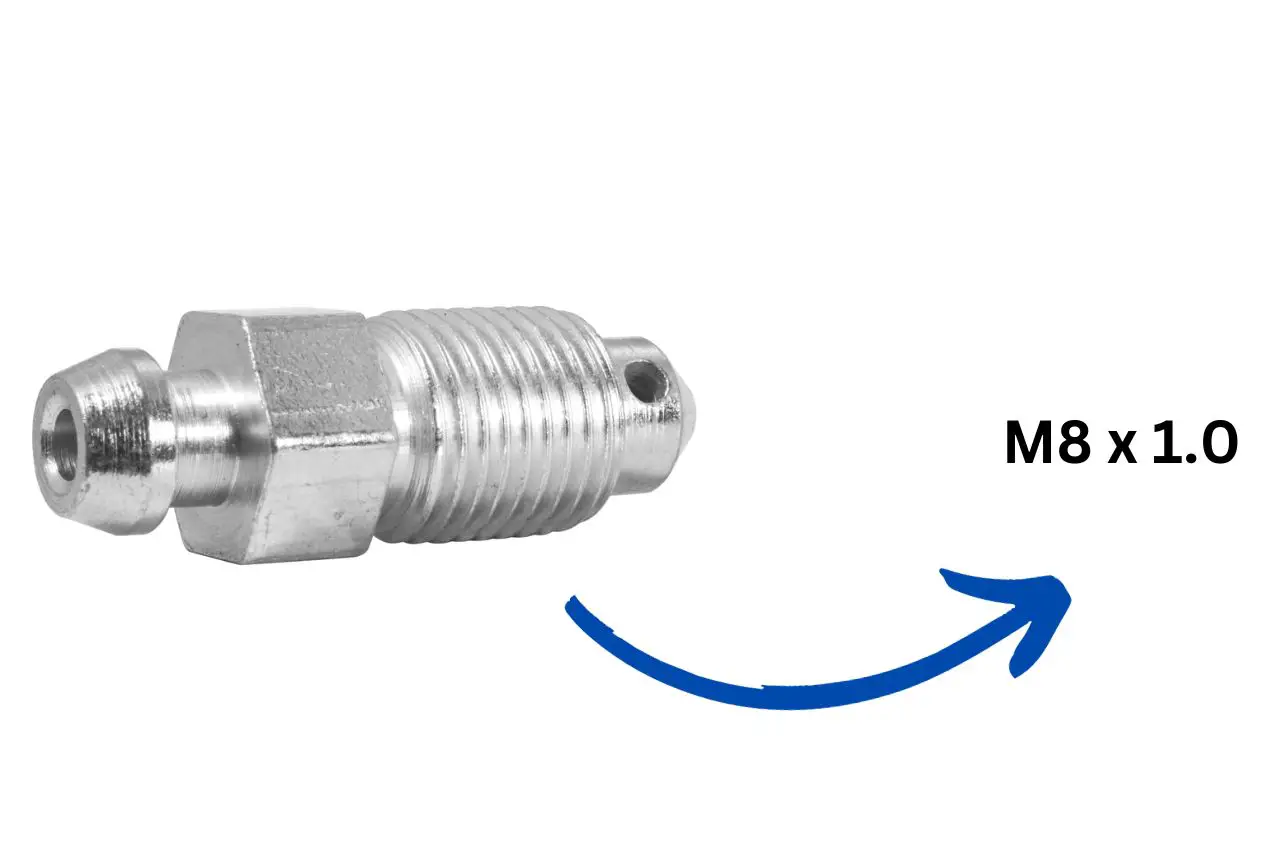

The size of a brake bleeder screw varies depending on the make and model of the vehicle. However, some of the most common brake bleeder screw sizes include:

It is important to use the correct size brake bleeder screw for your vehicle, as using the wrong size can damage the brake system. If you are unsure of the correct size brake bleeder screw for your vehicle, you can consult your vehicle’s owner’s manual or contact a qualified mechanic.

Here Are Some Additional Tips for Working with Brake Bleeder Screws:

It is also important to note that brake bleeder screws should be inspected regularly for signs of wear or damage. If you notice any problems with your brake bleeder screws, you should replace them immediately.

Understanding Brake Bleeder Screws:

Brake bleeder screws are an essential component of the braking system that helps remove air bubbles and maintain proper brake pressure. Here’s what you need to know about these small but crucial parts:

Remember that improperly functioning brake bleeder screws can lead to spongy brakes, reduced stopping power, or even complete loss of braking ability.

The Importance of Brake Bleeder Screw Size:

When it comes to brake maintenance, the size of the brake bleeder screw plays a crucial role in ensuring proper functioning and performance. Here’s why having the correct size matters:

To Ensure You Have the Appropriate Brake Bleeder Screw Size for Your Vehicle:

| Key Points |

|---|

| – Brake bleeder screw size affects bleeding efficiency and braking performance. |

| – Proper sealing is crucial to prevent fluid leaks. |

| – Correct sizing ensures compatibility with tools for easier maintenance. |

| – Improperly sized screws can cause damage to the braking system components. |

Remember that using an incorrect-size brake bleeder screw might lead to issues such as poor braking performance, fluid leaks, or even component damage. Therefore, always pay attention to this often-overlooked detail when performing brake maintenance on your vehicle.

Common Sizes for Brake Bleeder Screws:

When it comes to brake bleeder screws, there are several common sizes that you should be aware of.

These sizes may vary depending on the make and model of your vehicle, so always double-check your specific requirements before making any replacements or adjustments.

Here are some of the most commonly encountered sizes:

How to Determine the Correct Size for Your Brake Bleeder Screw?

When it comes to determining the correct size for your brake bleeder screw, there are a few steps you can follow. By taking these steps, you’ll be able to ensure that you select the right size and avoid any potential issues down the road.

| Step | Description |

|---|---|

| 1 | Check your vehicle’s manual |

| 2 | Measure with a caliper |

| 3 | Compare measurements |

| 4 | Seek professional assistance if needed |

Remember that selecting an incorrect size for your brake bleeder screw could lead to problems such as leaks or difficulty during maintenance procedures like bleeding brakes properly.

By following these steps, you’ll be well-equipped when it comes to determining the correct size for your brake bleeder screw, ensuring smooth and effective brake maintenance.

Tips for Replacing a Brake Bleeder Screw:

When it comes to replacing a brake bleeder screw, there are some important tips to keep in mind. Follow these guidelines to ensure a smooth and successful replacement process:

| Tip | Description |

|---|---|

| Safety First | Prioritize safety by wearing protective gear such as gloves and eyewear |

| Use The Right Tools | Ensure proper removal and installation with the correct wrench or socket set |

| Cleanliness is Key | Thoroughly clean the area around the screw to prevent debris from entering |

| Apply Penetrating Oil | Use a penetrating oil like WD-40 if there’s resistance when removing the old screw |

| Avoid Over-Tightening | Do not overtighten to avoid damaging threads and sealing surfaces |

| Use Thread Sealant (optional) | Consider using thread sealant for better sealing performance, depending on your vehicle model |

Conclusion: What Size Is a Brake Bleeder Screw 💭

The standard size of a brake bleeder screw is 5.16 inches x 3.8 inches. This specific measurement ensures compatibility and allows for proper functioning within the braking system.

Brake bleeder screws play a crucial role in removing air bubbles or contaminants from the brake lines, ensuring optimal performance and safety.

It is important to note that not all brake bleeder screws are created equal, as variations in size may exist depending on the make and model of your vehicle.

Therefore, it is essential to consult your vehicle’s manual or seek professional advice when replacing or repairing brake components.

By understanding the standard size of a brake bleeder screw, you can ensure that you select the correct replacement part and maintain an efficient braking system for your vehicle.

Remember to exercise caution and follow proper procedures when working with brakes to guarantee both personal safety and reliable performance on the road.

FAQs

What Is the Purpose of A Brake Bleeder Screw?

The main purpose of a brake bleeder screw is to allow air or old brake fluid to be expelled from the braking system during the bleeding process.

This helps to maintain the proper functioning of the brakes by ensuring that no air bubbles or contaminants are present in the system.

How Do I Determine the Size of My Brake Bleeder Screw?

To determine the size of your brake bleeder screw, you can use a caliper or ruler to measure the diameter of the threaded portion.

Alternatively, you can consult the vehicle’s manual or check with a professional mechanic for the correct size.

Can I Replace a Brake Bleeder Screw Myself?

Yes, in most cases, replacing a brake bleeder screw is a relatively simple task that can be done by a DIY enthusiast.

However, it is important to exercise caution and follow proper safety procedures when working with the braking system.

Are All Brake Bleeder Screws the Same?

No, brake bleeder screws can vary in size, design, and thread type, depending on the vehicle’s make and model.

It is important to use the correct replacement screw that matches the specifications of your vehicle to ensure proper fit and functionality.

Can a Damaged Brake Bleeder Screw Affect Brake Performance?

Yes, a damaged or improperly functioning brake bleeder screw can affect the overall performance of the braking system.

It can result in air or contaminants entering the system, which can lead to decreased braking efficiency, spongy brake pedal feel, or even brake failure.

Latest Posts:

- 10 Best Gear Oil for Limited Slip Differentials (Reviewed!)

- Allison 1000 Transmission Fluid Type (5 Best Options!)

- 91 Octane Vs 93 Which One You Use? (The Surprising Truth!)

- Oil Pressure Gauge Not Working: (Guaranteed Fix!)

- 10 Best Transmission Fluid for 4l60e (Tested by Experts!)

- 10 Best Ceramic Coating For Wheels (Used By Real Users!)